The Industrial Company (TIC) - Smart Concrete

2018-12-03

The Industrial Company (TIC)

Englewood, Colorado

Using SmartRock, the TIC team was able to strip forms 1.5 weeks ahead of schedule

PROBLEM

Relying on expensive wired devices to track concrete properties

In an industry where every project is time-sensitive, The Industrial Company (TIC) was searching for a more efficient method of testing concrete temperature and strength in their construction projects.

Prior to discovering SmartRock™ wireless maturity sensors, the TIC team depended on wired temperature loggers that cost nearly $3000 apiece and break tests that were slow and often gave unreliable results.

Photo Credit: The Industrial Company

SOLUTION

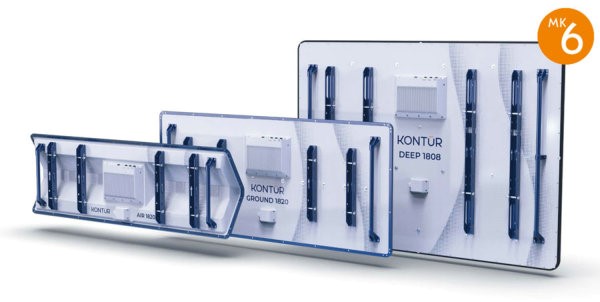

SmartRock™—a versatile, all-in-one solution for concrete testing

After visiting World of Concrete in Las Vegas, Christopher Webb, Concrete Superintendent for TIC, saw promise in Giatec’s SmartRock maturity meters and their versatility.

During the construction of a wood power plant in Alabama, SmartRock sensors were used to monitor temperature gradients in a 3000 cubic yard concrete foundation mass pour. Typically, for every 1000 cubic yards of concrete poured, TIC would use four sensors—two in the center of the placement and two near the surface.

“Overall a great, cost-efficient product,” Christopher Webb, TIC Project Manager.

The SmartRock sensors also proved to be a valuable tool in the scheduling of formwork removal, allowing the TIC team to strip forms days, and even weeks, ahead of schedule. Instead of waiting on labs for break test results, Webb was able to get accurate temperature, strength, and maturity data directly on his phone, then share it just as quickly with his co-workers.

RESULTS

Project schedules cut by weeks

With real-time concrete temperature and strength data delivered to his phone every 30 minutes, Webb and his team were able to strip forms the moment the concrete had reached the required strength. Ultimately, this allowed them to shorten their schedule in the Alabama power plant project by 1.5 weeks. Similar time savings and scheduling efficiencies were experienced in TIC’s other projects across Pennsylvania and California.

And even though cylinder breaks for testing concrete strength were still required by most project owners, the results were within 50 to 100 psi of the sensor data, proving once again the reliability of the SmartRock sensors.

Easy access to data & simplified data sharing

According to Webb, viewing results in the SmartRock phone app proved to be one of the most convenient features of the wireless sensors. He was able to see updated temperature and strength data every 30 minutes as well as to go back and review past data. Though the sensors’ battery is guaranteed to last up to four months, in some cases, Webb and his teammates were able to access concrete temperature data up to seven months after the installation of the sensor. Lastly, the ability to share PDF reports with engineers and field workers on site was also a huge time saver.

Reduced equipment costs

By switching to SmartRock, TIC eliminated the need for a $2,500 data logger.

“With SmartRock, all you’re paying for is the sensor. Everyone on the jobsite has a phone so there’s no need for an expensive reader,” emphasized Webb, adding that the SmartRock app is free and data can be shared with the entire team instantly, without having to go to the jobsite and plug cables into a cumbersome logger.

For the team, Giatec’s wireless maturity meters were the only logical choice given their low cost and innumerable advantages over traditional wired systems.

Technical support that goes above and beyond

Webb was equally impressed with Giatec’s technical and customer support, noting that the SmartRock agent on his account would check in with him every week to ensure that everything was running smoothly. On top of that, he found Giatec’s YouTube videos to be a great go-to resource for information regarding the installation and operation of the smart sensors.

From the initial installation of the sensors to viewing data and sharing reports, Webb describes the entire process as seamless. Given his positive experience using SmartRock, it’s no wonder that these concrete sensors are making a regular appearance in TIC projects all over North America.

Enquiry:hkmarketing@epc.com.hk

Enquiry:hkmarketing@epc.com.hk