Description

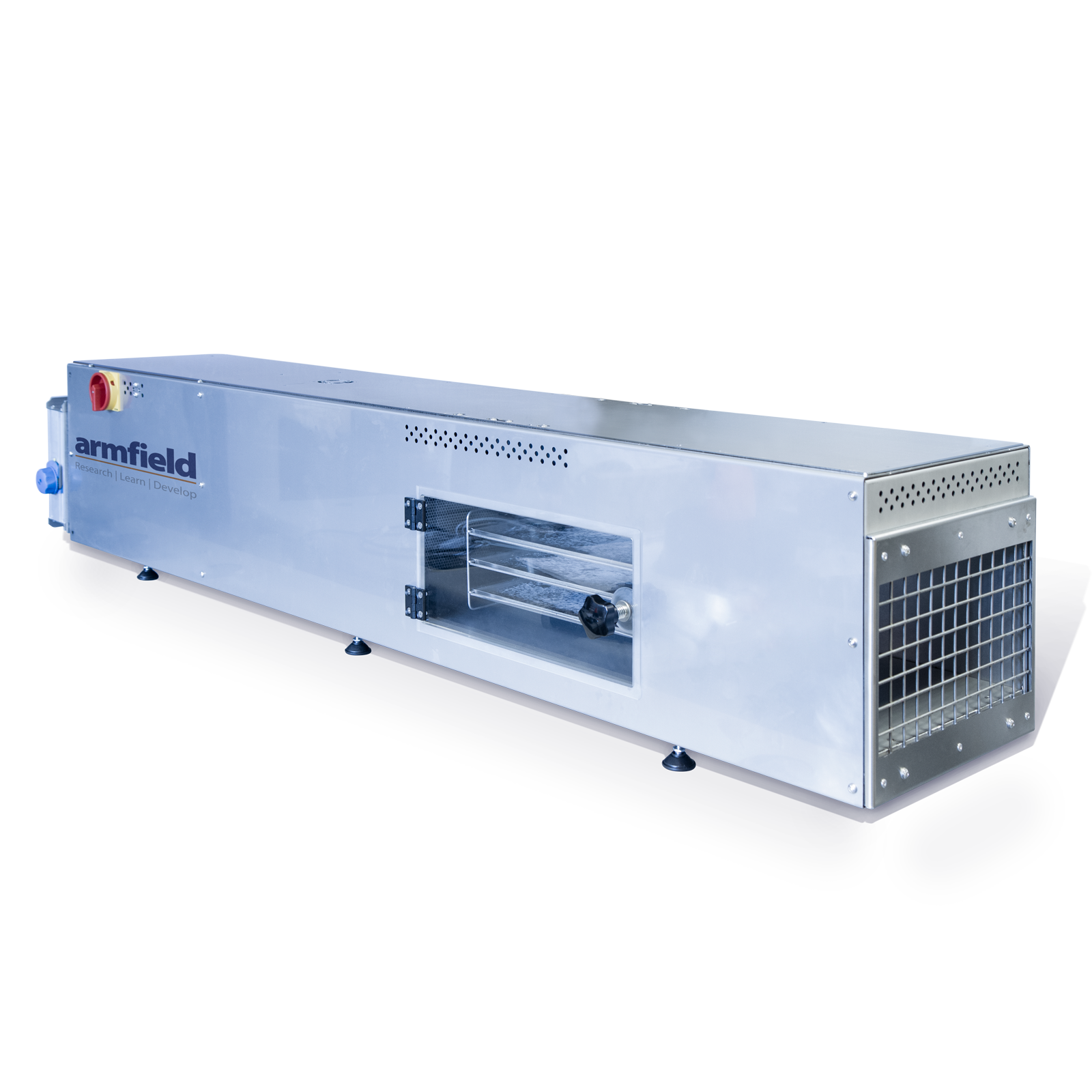

The UOP8-MkIIe comprises a square air duct fabricated from stainless

steel. Air is drawn into the duct through a mesh guard and flow damper

by an axial flow fan. The fan speed can be controlled to produce a

range of air velocities in the duct. The air passes over an electrically

heated element with electronic closed-loop control, which provides

stable air temperatures at the user-selected value.

A tray carrier is located in the central section of the duct, which can

hold up to three trays of material to be dried. The UOP8-MkIIe is

supplied with three lightweight coated aluminium trays suitable for

food applications. The trays are inserted or removed from the duct

through a latched side door with an acrylic panel for viewing purposes.

The total weight of the trays and the carrier is measured using three

load cells and is displayed on the software. A graph of weight against

time allows the drying regimes to be displayed and understood.

From the rate of change (slope) of this graph the drying rate can be

determined.

Comprehensive instrumentation is included and the measured values

recorded on the computer:

Weight of trays plus contents (with tare function)

Temperature (dry bulb) and relative humidity of the heated air before the trays

Temperature and relative humidity of the air after passing over the trays

Air velocity

From each pair of temperature and relative humidity readings the full thermodynamic properties of the air can be determined using a

psychrometric chart, ie the wet bulb temperature, the moisture content and the changes in enthalpy. This allows for a more in-depth analysis

for project or research work, for example comparing the change in moisture content of the air with the rate of moisture loss from the trays.

The user must have a PC with a USB port, running Windows 7 or above.

Armfield,UOP8MKII,Computer Controlled Tray Dryer

Enquiry:hkmarketing@epc.com.hk

Enquiry:hkmarketing@epc.com.hk