VARIABLE DIRECTION DYNAMIC CYCLIC SIMPLE SHEAR

Product Code : VDDCSS

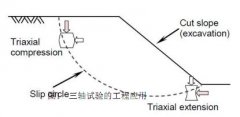

The variable direction dynamic cyclic simple shear system (VDDCSS) allows simple shear to be performed in two directions, rather than the standard single direction. This is achieved by having a secondary shear actuator that acts at 90 degrees to the primary actuator.

When used as a variable direction machine, the secondary shear axis can be used independently or in conjunction with the other shear axis. Therefore, simple shear may be performed in any horizontal direction. Used for simulating change in wind direction on a wind turbine without having to remove the sample. To see a comparison table of selected GDS shear products, click on the link,

|

Key features |

Benefits to the user |

|---|

|

Test control: |

Test control allows specification of amplitude of shear stress/strain as well as direction. |

|

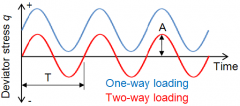

Direction of shear and pattern of shear rotation from zero degrees can be defined: | Constant at zero degrees. Rotate from zero degrees at a constant rate. Cycles from zero degrees plus or minus x degrees with period in seconds.

|

|

Teflon coated rings: |

K-zero conditions ensured by use of 1mm high, low-friction, teflon coated rings. |

|

Control & Acquisition software can also define test stages at different shear stress: |

Angles relative to zero e.g. 0, 10, 20, 30 etc. Definition of waveform by datum/common point, amplitude, controlling parameter and frequency. |

|

Independent axis control: |

Each axis can be load or displacement controlled. |

|

Local strain LVDT’s for both shear directions: |

Highly accurate strain measurement. |

|

Actuators |

3 x electromechanical, high accuracy, encoder controlled actuators. |

|---|

|

Axial Force Accuracy |

Typically <0.1% |

|---|

|

Axial Load |

5kN |

|---|

|

Displacement Range |

Shear axis +/- 10mm (+/-30% shear strain), Normal axis +/- 25mm (+80% consolidation strain). |

|---|

|

Displacement Resolution |

0.3um |

|---|

|

Load Range (kN) |

5kN normal force, 2kN on each shear measurement (y and z). |

|---|

|

Operating Frequency (Hz) |

1Hz |

|---|

|

Sample Sizes |

50mm & 70 diameter, 20 to 30mm height |

|---|

Enquiry:hkmarketing@epc.com.hk

Enquiry:hkmarketing@epc.com.hk